China Brick Making Machine Manufacturers

About Us

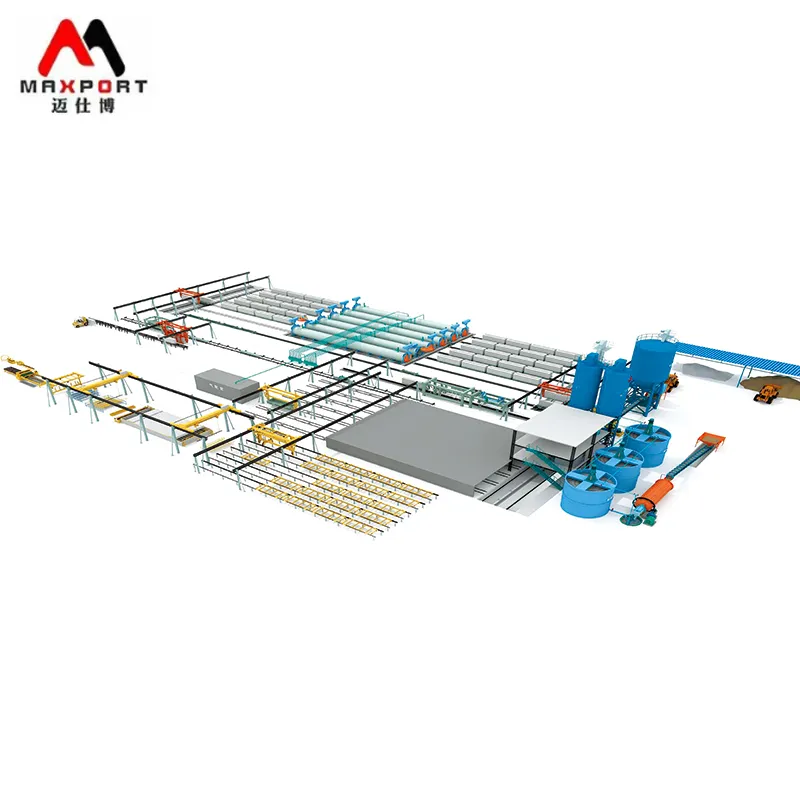

Maxport QT12 - 15

- Pallet size: 1300*900mm

- Product molding height: 45-230mm

- Molding cycle: 15-25S/time

- Main vibration form: Table vibration

- Vibration frequency: 2800-5100 times/minute

- Main machine dimensions: 9350*3200*2900mm

- Main machine power : 67kw

- Rated pressure: 21 MPA

- Excitation force: 110 KN

- Host Machine Weight: 11500KG

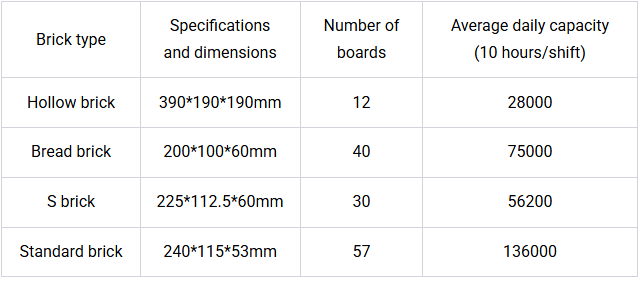

Brick Size & Daily Production Capacity

| Brick type | Specifications and dimensions | Number of boards | Average daily capacity (10 hours/shift) |

| Hollow brick | 390*190*190mm | 12 | 28000 |

| Bread brick | 200*100*60mm | 40 | 75000 |

| S brick | 225*112.5*60mm | 30 | 56200 |

| Standard brick | 240*115*53mm | 57 | 136000 |

Why Choose Us

Excellent product quality

As a veteran wooden furniture manufacturer, maxport always regards quality as the lifeline of the enterprise.

Support customization

Whether you need a small machine or a large brick making machine, we can tailor it for you. Support customer customization services.

One-stop caring service

You can find high-quality production machines for any brick type you need here.

Professional team

We have a professional design and service team. The design team is "customer-centric" and recommends the best solution for you based on the market in your area.

Brick Making Machine: Revolutionizing Construction with Efficiency and Scale

Modern brick making machines are primarily categorized into four types based on their level of automation. Manual brick machines operate using mechanical lever principles and rely entirely on human labor. Although their daily output is limited (approximately 100–500 bricks), they feature low investment costs, simple operation, and easy maintenance, making them particularly suitable for startups with limited capital or small projects in remote areas. Semi-automatic brick machines retain manual feeding while automating the compression and demolding processes. With a daily output of 500–2,000 bricks, they strike an optimal balance between efficiency and cost, making them highly popular among small and medium-sized building material enterprises.

Fully automatic brick machines represent the highest level of technological advancement in the industry. They employ computer control systems to achieve end-to-end automation, from raw material feeding and proportional batching to high-pressure molding, automatic curing, and finished product stacking. Their daily output can exceed 2,000–10,000 bricks. Although the initial investment is substantial, they offer significant long-term labor cost savings and product quality consistency. Mobile brick machines innovatively adopt a modular design, integrating the entire production line onto a movable platform that can be driven directly to construction sites for operation. This greatly reduces logistics costs and is especially suitable for large infrastructure projects and construction needs in remote areas.

CONTACT US

Address: Lanshan District, Linyi City, Shandong Province, China

- Whatsapp: +86 18866984005

- Email: info@sdmaxport.com