China Brick Making Machine Manufacturers

About Us

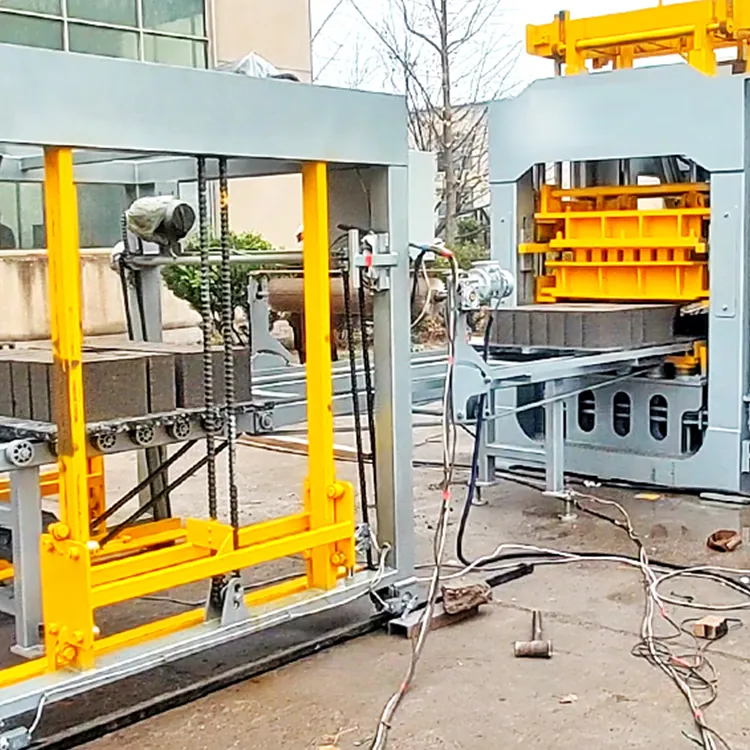

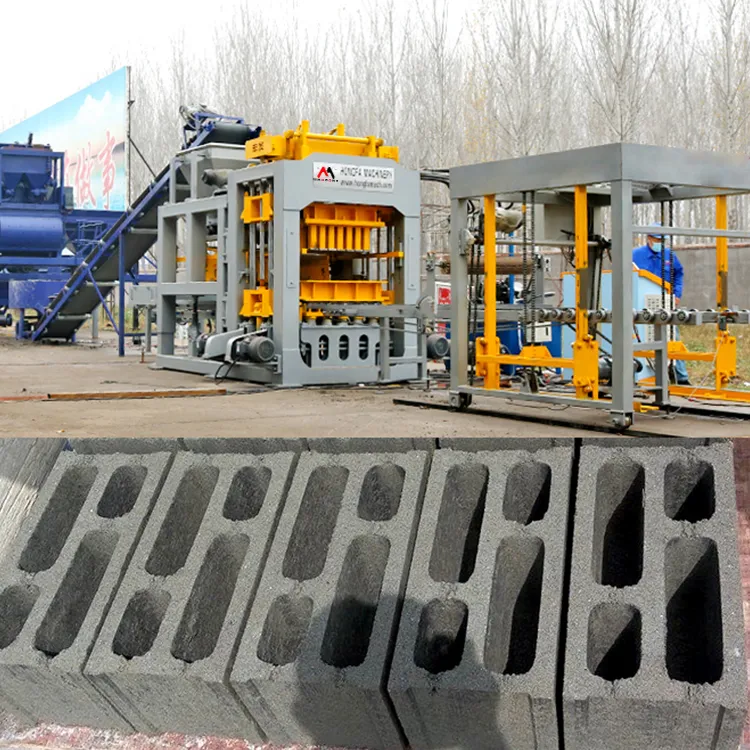

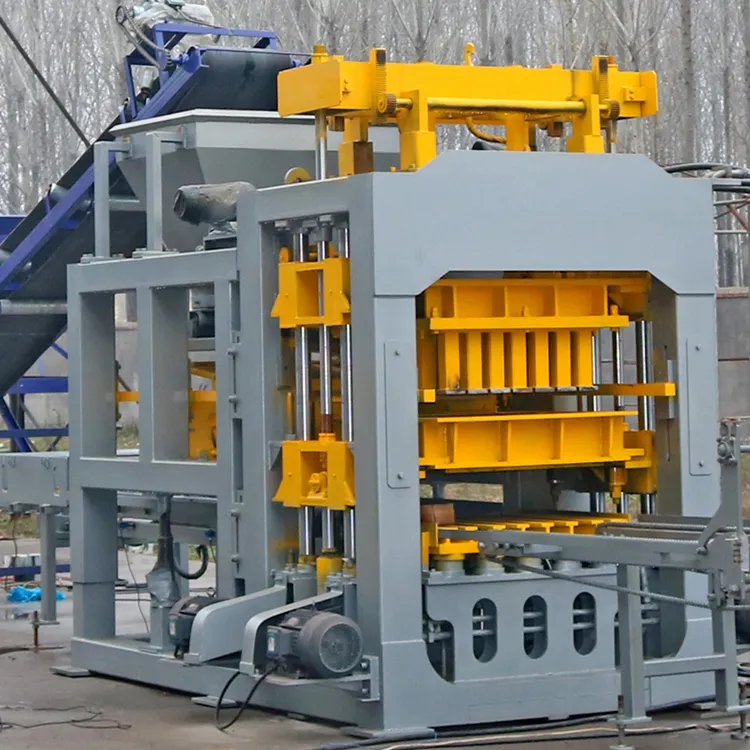

Maxport QT8 - 15

- Pallet size: 950*900mm

- Product molding height: 45-230mm

- Molding cycle: 15-25S/time

- Main vibration form: Table vibration

- Vibration frequency: 2800-5100 times/minute

- Main machine dimensions: 8300*2800*2850mm

- Main machine power : 51kw

- Rated pressure: 21 MPA

- Excitation force: 85KN

- Host Machine Weight: 9450KG

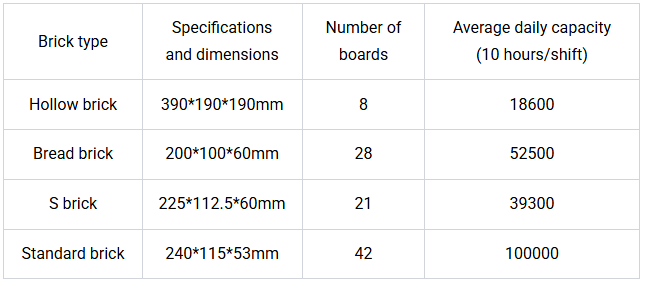

Brick Size & Daily Production Capacity

| Brick type | Specifications and dimensions | Number of boards | Average daily capacity (10 hours/shift) |

| Hollow brick | 390*190*190mm | 8 | 18600 |

| Bread brick | 200*100*60mm | 28 | 52500 |

| S brick | 225*112.5*60mm | 21 | 39300 |

| Standard brick | 240*115*53mm | 42 | 100000 |

Why Choose Us

Excellent product quality

As a veteran wooden furniture manufacturer, maxport always regards quality as the lifeline of the enterprise.

Support customization

Whether you need a small machine or a large brick making machine, we can tailor it for you. Support customer customization services.

One-stop caring service

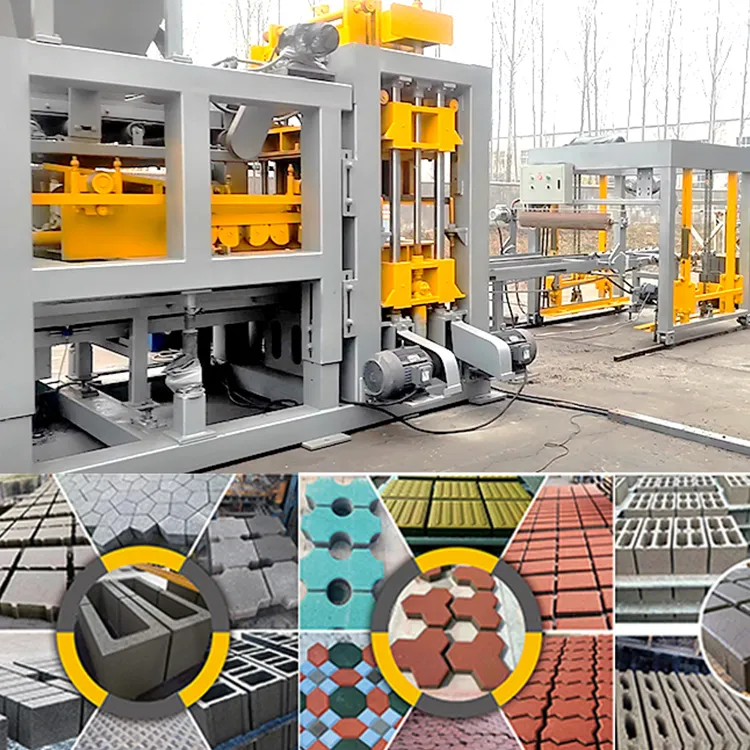

You can find high-quality production machines for any brick type you need here.

Professional team

We have a professional design and service team. The design team is "customer-centric" and recommends the best solution for you based on the market in your area.

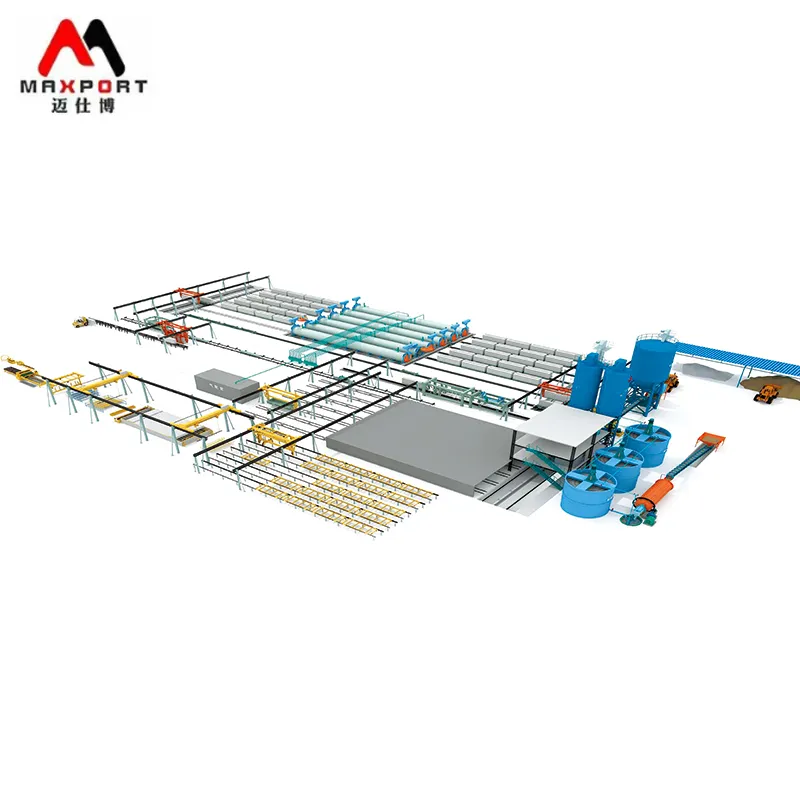

Scientific Process Guarantees Product Quality

The modern brick-making process comprises four key stages. In the raw material preparation phase, precise proportioning and uniform mixing of materials such as cement, aggregate, and fly ash are required to ensure the mixture reaches the optimal molding state. During the molding stage, high-pressure vibration or static compression methods are used to rapidly compact loose materials into shape within the mold. The curing phase employs natural drying or steam curing processes to enable the bricks to achieve their designed strength by controlling temperature and humidity. The final packaging stage uses automatic stacking robotic arms and packaging equipment to ensure neat storage and convenient transportation of finished bricks. The entire process adopts standardized operations, effectively guaranteeing consistent product quality.

CONTACT US

Address: Lanshan District, Linyi City, Shandong Province, China

- Whatsapp: +86 18866984005

- Email: info@sdmaxport.com