China Brick Making Machine Manufacturers

About Us

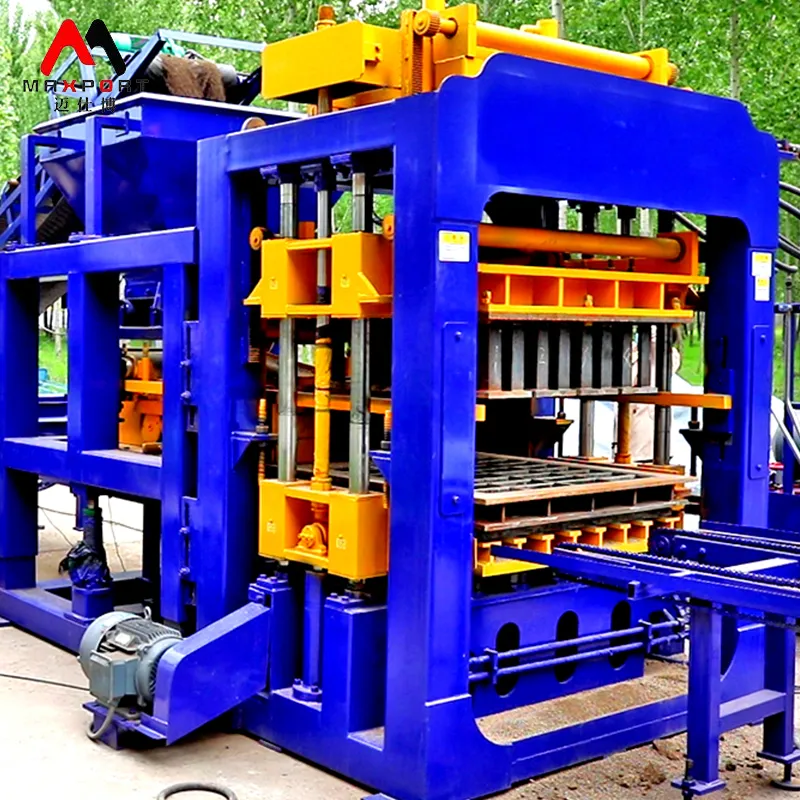

Maxport QT10 - 15

- Pallet size: 1100*900mm

- Product molding height: 45-230mm

- Molding cycle: 15-25S/time

- Main vibration form: Table vibration

- Vibration frequency: 2800-5100 times/minute

- Main machine dimensions: 9350*3000*2900mm

- Main machine power : 67kw

- Rated pressure: 21 MPA

- Excitation force: 110 KN

- Host Machine Weight: 10500KG

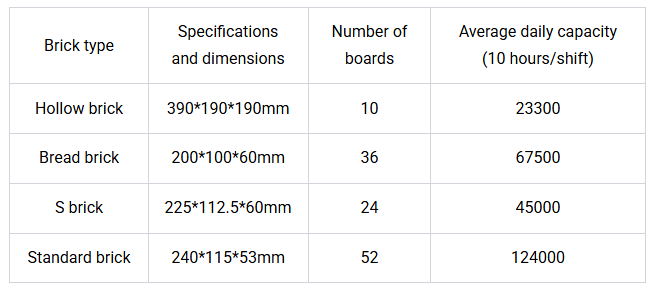

Brick Size & Daily Production Capacity

| Brick type | Specifications and dimensions | Number of boards | Average daily capacity (10 hours/shift) |

| Hollow brick | 390*190*190mm | 10 | 23300 |

| Bread brick | 200*100*60mm | 36 | 67500 |

| S brick | 225*112.5*60mm | 24 | 45000 |

| Standard brick | 240*115*53mm | 52 | 124000 |

Why Choose Us

Excellent product quality

As a veteran wooden furniture manufacturer, maxport always regards quality as the lifeline of the enterprise.

Support customization

Whether you need a small machine or a large brick making machine, we can tailor it for you. Support customer customization services.

One-stop caring service

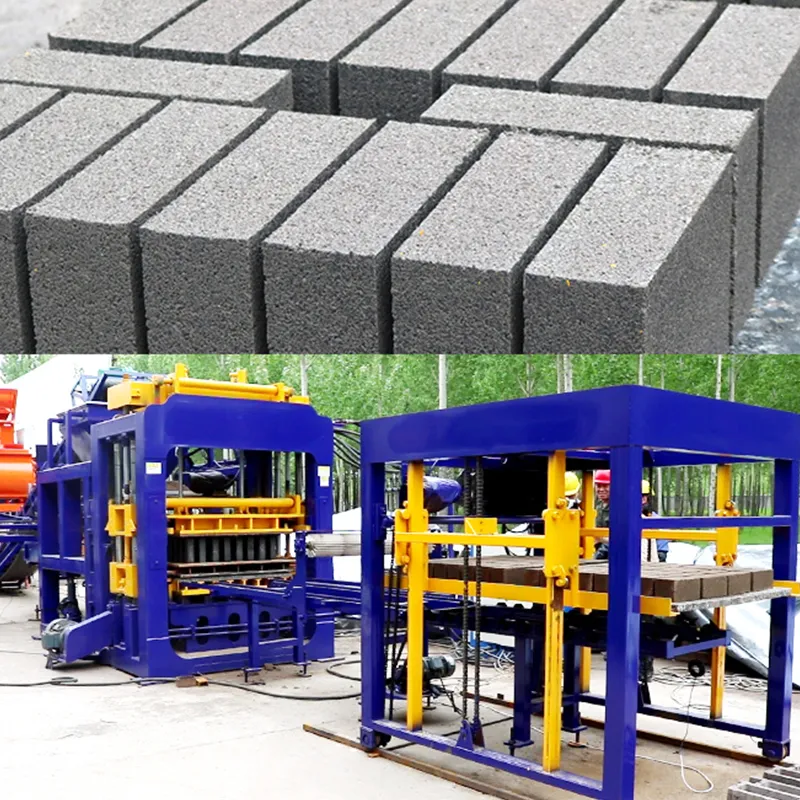

You can find high-quality production machines for any brick type you need here.

Professional team

We have a professional design and service team. The design team is "customer-centric" and recommends the best solution for you based on the market in your area.

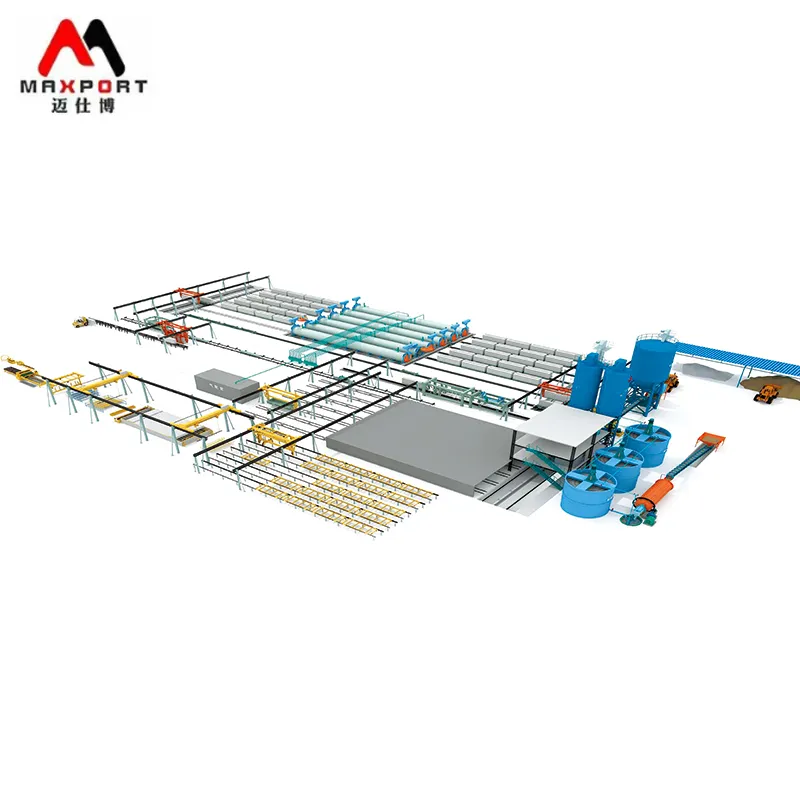

Precision Engineering Ensures Efficient Production

A complete brick making machine consists of multiple precisely coordinated component systems. The hopper, serving as the raw material inlet, is equipped with a mixing device to ensure uniform material blending. The mold cavity, made of special steel and precision-machined, can produce various specifications of solid, hollow, or special-shaped bricks. The hydraulic system provides stable high-pressure power to ensure brick density and strength. The intelligent control system features a human-machine interface for precise adjustment of pressure, time, and production parameters. The conveyor system automatically transports molded bricks to the curing area, enabling continuous production. The efficient coordination of these components ensures the reliability and stability of the machine’s operation.

CONTACT US

Address: Lanshan District, Linyi City, Shandong Province, China

- Whatsapp: +86 18866984005

- Email: info@sdmaxport.com